Cryogenic Sandblasting

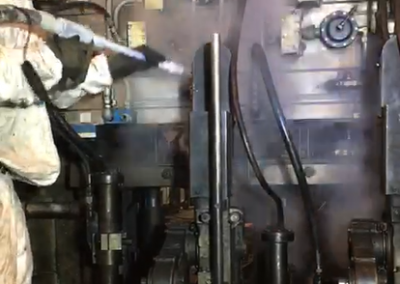

Cryosandblasting is a system based on the principle of traditional sandblasting, but it uses dry ice pellets, specifically solid carbon dioxide, as the cleaning agent. It is a highly effective alternative to conventional cleaning methods.

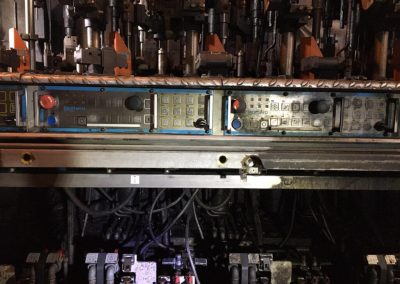

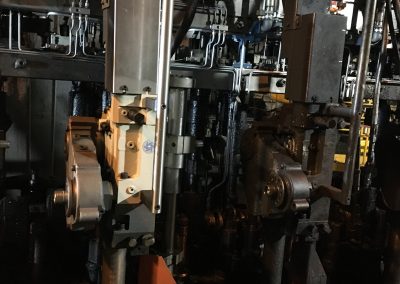

In industrial applications, cryosandblasting provides the opportunity to clean machinery without the need to disassemble components such as molds or mechanical parts. This significantly reduces cleaning times, improves productivity and quality, and, most importantly, recovers time otherwise lost to the assembly and disassembly of mechanical parts.

Cryogenic sandblasting offers the following advantages:

- Waste reduction: No waste products to dispose of except for the removed material.

- Reduced machine downtime.

- Absence of solvents.

- Absence of water and moisture: It can be used even in the presence of electrical panels.

- Non-abrasive: Suitable for treating delicate surfaces; can be used for paint removal on wood.

- No dust generation, except for that resulting from the dislodged dirt

- Minimal environmental impact.

- Compliant with FDA/BGA regulations.

The dry ice pellets ensure cleaning through two combined effects:

- Mechanical effect: Resulting from the impact and pressure exerted by CO2.

- Thermal effect: Through the rapid decrease in temperature, which hardens the dirt, making it brittle and easy to remove.